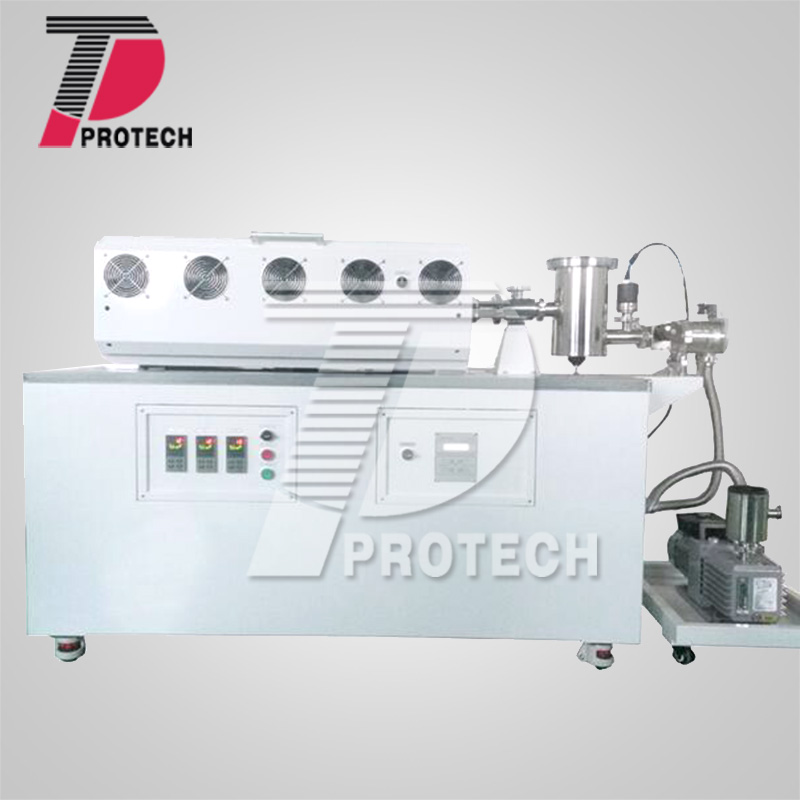

| Sublimation furnace |

| Power |

5KW |

| Voltage |

AC220V 50/60Hz |

| heating element |

resistance wire |

| heating zone |

three zones,three points temp. control independently |

| length of zone |

200+300+200mm(customizable) |

| Sublimation area and insulation zone temperature |

Continuously adjustable from room temperature to 800 ° C |

| Temperature Controller |

PID automatic and double control by digital industrial instrument and PLC |

| Paperless record |

Built-in storage record running process data, external USB interface, you can connect one-click copy data with computer. |

| Structure |

F4KMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

half openF4KMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The feeding end is equipped with a high-precision mass flow meter to accurately control the gas flow, which can realize the expansion and adjustment of the production process.F4KMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Automated process flow is used to set the process for one-button operation. Reduce human factors and achieve a process reliability of 99.9%.F4KMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

|

| Filter |

Multi-level filter protection device including Microporous metal filter ,condensation trap liquid nitrogen embedded |

| Plasma system |

| chamber |

F4KMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

The inner and outer quartz tube devices ensure that the vacuum chamber tubes are free from contamination and are easy to clean.F4KMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

After the inner layer tube is sublimated, the sections are easy to distinguish, which can ensure the purity and yield of the product to the utmost extent.F4KMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Outer tube (single-end sealing): 60/100*1000mm, the inner tube is customized according to requirements |

| Vacuum unit |

| |

Direct connection with the main tube and molecular pump to ensure high vacuum in the experiment, the vacuum can reach 10 -4Pa |

| Fore pump |

pumping rate:165L/Min |

| Molecular pump |

pumping rate:49L/S(KF40)F4KMuffle Furnace,Tube Furnace,Vacuum Furnace,Atmosphere Furnac

Rotating speed:81000rpm |